Tufftride® - Q.P.Q. Process

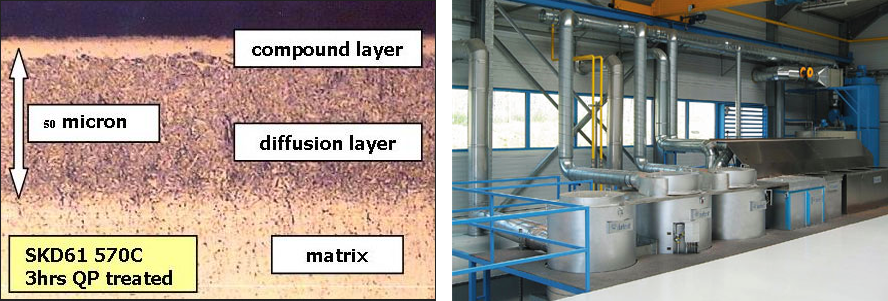

Salt bath nitrocarburizing by the TUFFTRIDE ® process has been applied in a wide range of industries throughout the world for many decades. It is used to improve the wear resistance, the fatigue strength and – in particular when combined with the oxidative cooling – the corrosion resistance of components made from steel, cast iron and sintered iron materials. In many cases the TUFFTRIDE® process is used as an alternative to other surface engineering processes such as case hardening, galvanic (e.g. hard chrome plating), and other coating processes (plastic coating, painting, laser coating etc.), also plasma or gas nitrocarburizing with equally good or improved quality and greater economy.

In addition to the improvements in the properties such as wear protection, fatigue strength and sliding properties, the TUFFTRIDE® treatment plus oxidative cooling or QPQ ® produces a major increase in the corrosion resistance. Results of tests and practical applications show that the quality of the treated components is often superior to that of electro galvanic layers and other nitrocarburizing processes. This opens a broad field of application for the TUFFTRIDE® or QPQ ® process, which can often be accompanied by expensive materials being replaced by lower-cost ones. Due to the characteristics of the process, such as very good repeatability of high quality results, easy use and high flexibility, it is being used to an ever-increasing extent in the metal processing industry all over the world. The process is very easy to carry out and does not require complicated plant technology. The parts can be treated in manually operated and computer-controlled plants. The plant itself operates effluent-free. The process is characterized by its extremely good environment-compatibility. Therefore, environmental regulations can easily be complied with.

Benefits of Tufftride®

- Increased surface hardness

- Improved fatigue strength

- Increase in corrosion resistance

- Increased wear resistance

- Reduces scuffing