Metal Hardening

The use of this treatment will result in an improvement of the mechanical properties, as well as an increase in the level of hardness, producing a tougher, more durable item. Alloys are heated above the critical transformation temperature for the material, then cooled rapidly enough to cause the soft initial material to transform to a much harder, stronger structure. Alloys may be air cooled, or cooled by quenching in oil, water, or another liquid, depending upon the amount of alloying elements in the material. Hardened materials are usually tempered or stress relieved to improve their dimensional stability and toughness.

Steel parts often require a heat treatment to obtain improved mechanical properties, such as increasing increase hardness or strength. The hardening process consists of heating the components above the critical (normalizing) temperature, holding at this temperature for one hour per inch of thickness cooling at a rate fast enough to allow the material to transform to a much harder, stronger structure, and then tempering.

Steel is essentially an alloy of iron and carbon; other steel alloys have other metal elements in solution. Heating the material above the critical temperature causes carbon and the other elements to go into solid solution. Quenching “freezes” the microstructure, inducing stresses. Parts are subsequently tempered to transform the microstructure, achieve the appropriate hardness and eliminate the stresses.

Metal Tempering

Tempering is done to develop the required combination of hardness, strength and toughness or to relieve the brittleness of fully hardened steels. Steels are never used in the as quenched condition. The combination of quenching and tempering is important to make tough parts.

This treatment follows a quenching or air-cooling operation. Tempering is generally considered effective in relieving stresses induced by quenching in addition to lowering hardness to within a specified range or meeting certain mechanical property requirements.

Tempering is the process of reheating the steel at a relatively low temperature leading to precipitation and spheroidization of the carbides present in the microstructure. The tempering temperature and times are generally controlled to produce the final properties required of the steel. The result is a component with the appropriate combination of hardness, strength, and toughness for the intended application. Tempering is also effective in relieving the stresses induced by quenching.

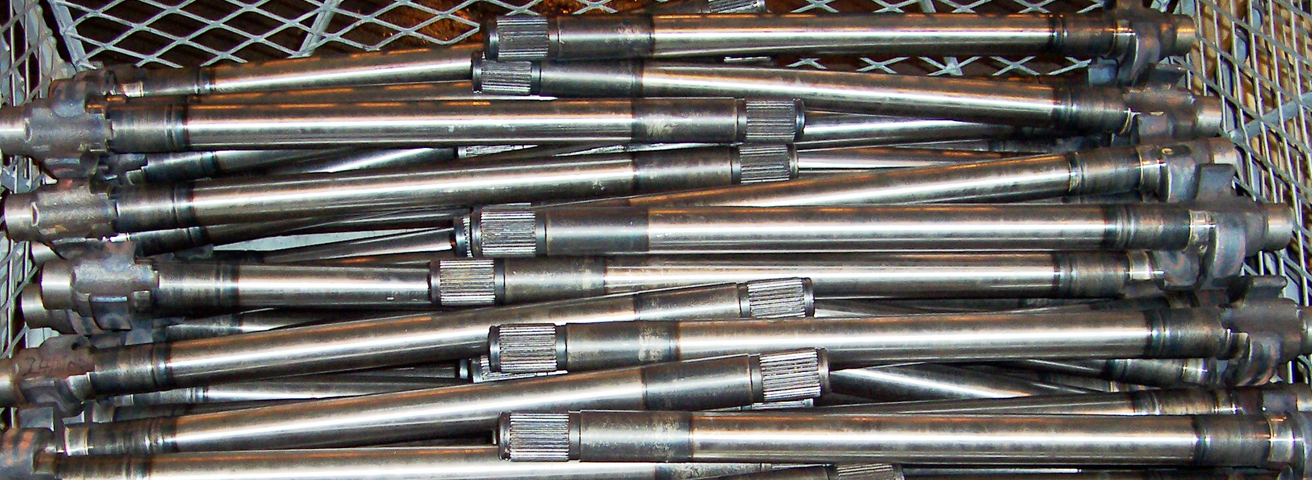

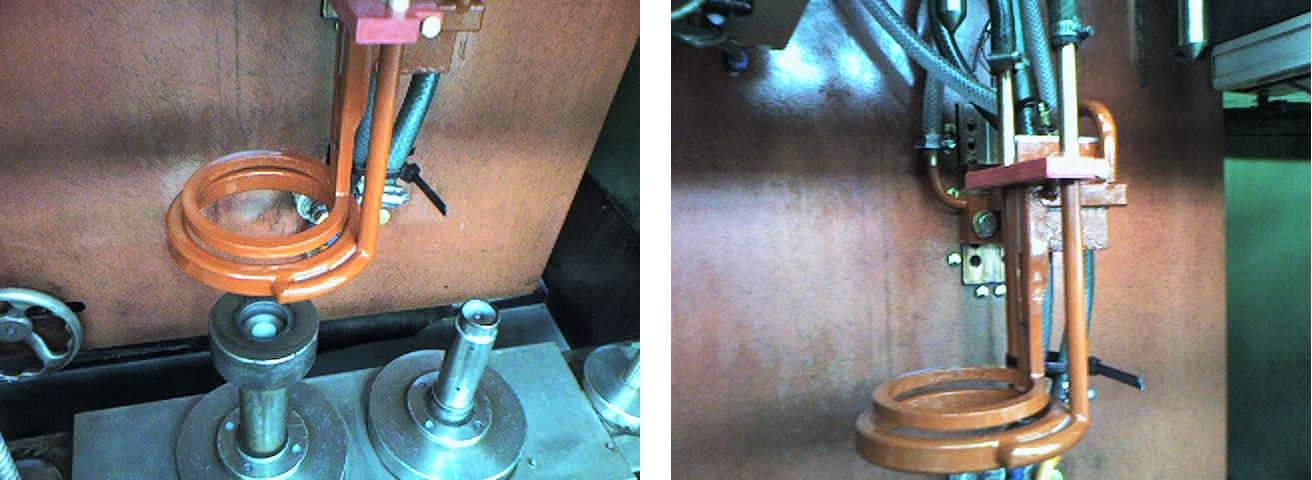

Induction Hardening

Induction hardening is a process used for the surface hardening of steel and other alloy components. The parts to be heat treated are placed inside a water cooled copper coil and then heated above their transformation temperature by applying an alternating current to the coil. The alternating current in the coil induces an alternating magnetic field within the work piece, which if made from steel, caused the outer surface of the part to heat to a temperature above the transformation range. Parts are held at that temperature until the appropriate depth of hardening has been achieved, and then quenched in oil, or another media, depending upon the steel type and hardness desired.

The core of the component remains unaffected by the treatment and its physical properties are those of the bar from which it was machined or preheat treated. The hardness of the case can be HRC 37 – 58. Carbon and alloy steels with a carbon content in the range 0.40 – 0.45% are most suitable for this process. In some cases, parts made from alloy steels such as 4320, 8620 or 9310, like steel and paper mill rolls, are first carburized to a required case depth and slow cooled, and then induction hardened. This is to realize the benefit of relatively high core mechanical properties, and surface hardness greater than HRC 60, which provides excellent protection.

While induction hardening is most commonly used for steel parts, other alloys such as copper alloys, which are solution treated and tempered, may be induction hardened as well. Applications include hardening bearing races, gears, pinion shafts, crane (and other) wheels and treads, and threaded pipe used for oil patch drilling.

Benefits

Strengthening of metal and alloys, like steel and aluminum, occurs through heat treatment. The applications of many of these metals are in airplanes, cars, computers, and others. These products rely on metals with high increased strength. This is to ensure adequate safety and improved performance.