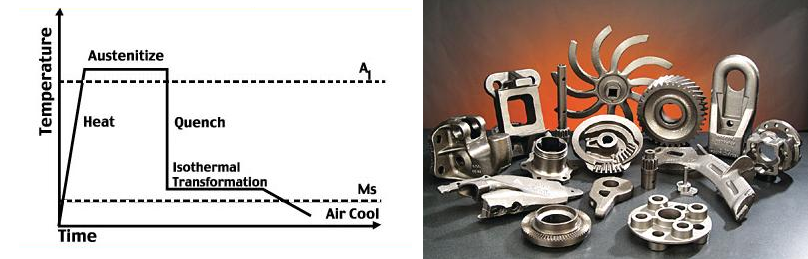

Austempered Ductile Iron

Austempered Ductile Iron (ADI) is a specialty heat treated material that takes advantage of the near-net shape technology and low cost manufacturability of ductile iron castings to make a high strength, low cost, excellent abrasion-resistant material. Six grades of ADI are available to address property combinations of high strength, abrasion resistance and toughness for converting from costly forgings, weldments and assemblies.

It may surprise you to know that in some applications ADI has replaced aluminum as a weight savings. ADI components are very competitive with steel forgings, castings, weldments, and aluminum forgings and castings.

Austempered Ductile Iron (ADI) has found successful applications across many industries, including Construction and Mining, Agriculture, Automotive, Heavy Truck, and Railroad.

Typical applications include:

- Timing Gears

- CV Joints

- Steering Knuckles

- Sprockets, Rollers, Idlers

- Suspension Housings and brackets

- Wear Plates

- Wheel Hubs

- Control Arms

- Plow Points

- Hitches

- Crankshafts

- Flanged shafts

Austempered Steel

This dimensionally repeatable process is typically cost competitive with conventional quench and temper processes. Austempering is particularly appropriate for medium and high carbon stampings, forgings, castings, and full density powdered metal parts.

Austempered Steel offers superior toughness at high hardnesses over conventionally quenched and tempered steel. This process exhibits minimal distortion, no cracking during quenching and resistance to hydrogen embrittlement. Austempered Steel (including high-density Austempered Powdered Metals) is superior to conventionally processed steels.

Typical examples of Austempered Steel applications are:

- Mower Blades

- Clips and Clamps

- Cutter and Mixer Blades

- Transmission Gears

- Wave Plates

- Turf Aeration Tines